“Hypoxia” used to be nothing but a niche biology topic. Today it is quietly becoming standard infrastructure in labs.

Two forces are converging. Regulators and funders are nudging R&D away from default animal studies and toward human-relevant evidence. At the same time, more researchers are acknowledging that many in vitro models are still run under conditions that are convenient, not physiological. Oxygen is the simplest example of this.

Here’s what this essentially means for the market: if more screening, mechanism work, and early safety decisions happen in human-derived in vitro systems, then the tools that make those systems more reliable and enhance translation will see increased demand. Hypoxia workstations, oxygen-controlled incubators, and oxygen monitoring tools sit directly in the path of that wave.

Regulatory tailwinds: More NAM-ready workflows

In April 2025, The U.S. Food and Drug Administration announced a plan to reduce, refine, or potentially replace animal testing requirements for monoclonal antibodies and other drugs using New Approach Methodologies (NAMs). It also released a roadmap describing how validated non-animal methods could increasingly support preclinical safety evaluation. The FDA said implementation would begin immediately for investigational new drug applications where NAM data are encouraged.

The National Institutes of Health are also moving in the same direction. The NIH announced an initiative to expand innovative, human-based science while reducing animal use. Later, it stated that new funding opportunities involving animal model systems must also support human-relevant approaches, including clinical trials, real-world data, and NAMs such as organoids and microphysiological systems.

Beyond the U.S., the UK government published a detailed strategy in late 2025 that aims to replace animals with alternative methods wherever possible and to accelerate development, validation, and uptake of non-animal approaches. Canada has similarly published a strategy to replace, reduce, or refine vertebrate animal testing in chemical testing. The U.S. EPA continues to maintain NAM-focused work aimed at reducing vertebrate animal testing.

Whether it’s pharma, biotech, or academia, everyone’s being pulled in the same direction, just at different speeds. The message is clear: build stronger alternatives to animal testing.

Scientific tailwinds: Physioxia is becoming a baseline expectation

As in vitro models take on a bigger role in labs, standards for how we grow and maintain them must rise too. One of the clearest gaps between lab convenience and real biology is still the default workflow: cells grow in a standard CO₂ incubator (often around 17–19% O₂) and then get handled on the bench in room air (about 21% O₂).

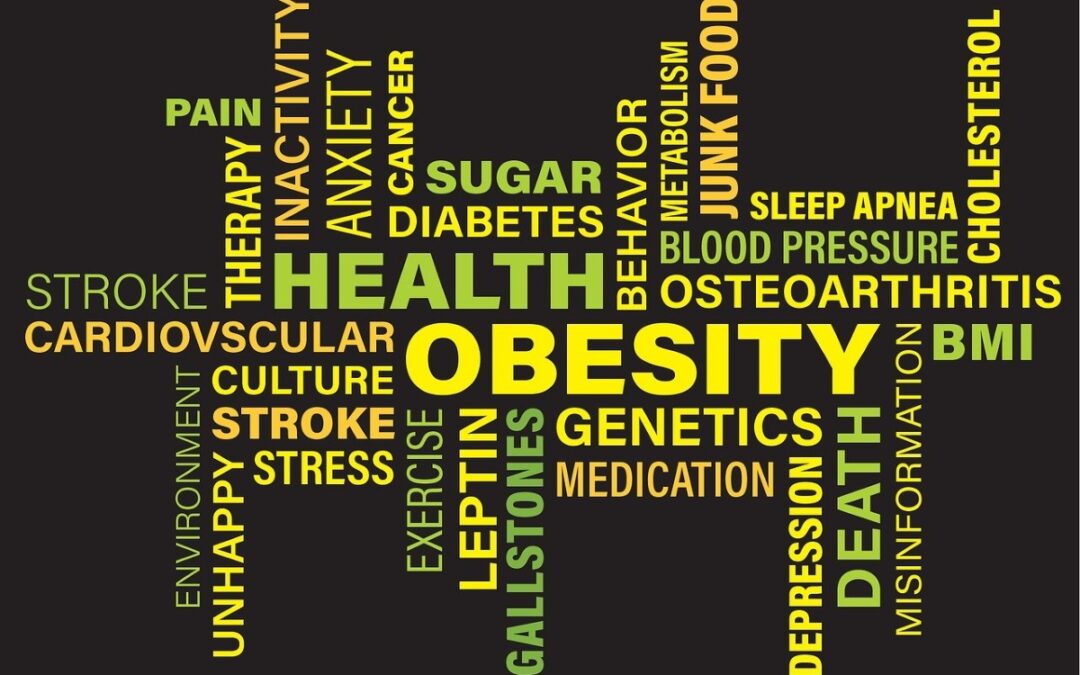

The “physioxia” literature has been making this point for years: in many tissues, physiologically relevant oxygen levels often fall somewhere between roughly 11% and 1% O₂. In that context, conventional “normoxia” cell culture can be misleading because it bakes in a non-physiological condition from the start. Recent reviews consistently show that elevated oxygen can shift redox biology, gene expression programs, mitochondrial function, and even drug responses, ultimately making standard CO₂-incubator models less translational.

There is also a second-order issue: what cells experience can differ from their incubator setpoint. Pericellular oxygen depends on gas transfer, diffusion through media, media height, plate geometry, and cellular consumption. In 2024, research reported oxygen limitation across multiple culture models and described improvements in model quality when pericellular oxygen was considered explicitly.

When a biological variable as fundamental to cells as oxygen can change a phenotype, it will become a market driver. Physioxia is increasingly treated less like an advanced option and more like basic experimental hygiene, especially in organoids, microphysiological systems, immune co-cultures, and metabolic disease models.

Market pull: Sponsors, CROs, and investment in NAMs

One of the clearest places to see demand forming is in the CRO ecosystem around drug development. A Reuters report on AI-driven drug discovery and safety testing noted that FDA pressure to reduce animal testing is catalyzing investment in human-relevant methods and services.

CROs typically adopt new tools when sponsors start demanding them and when regulators reward the resulting data. If organoid-based tox packages, organ-on-chip validation studies, or physioxic disease models become routine early gates, then oxygen control equipment that keeps these workflows reproducible will start to look like standard infrastructure, not a speciality product.

Where the next demand comes from

In practice, the next wave of purchasing is likely to come from three places.

First are academic and hospital core facilities building shared organoid and microphysiological systems. These platforms are powerful, but they are sensitive to hidden variables, and oxygen is a major one.

Second are CROs productizing NAM services. When sponsors pay for “human-relevant” packages, CROs need workflows that are stable, repeatable, and defensible, which favors enclosed handling and traceable oxygen control.

Third is bioprocessing and cell therapy R&D. Many teams optimize potency, differentiation, and stress responses in human cells, and oxygen is routinely one of the controllable levers. As these programs mature, oxygen-controlled culture moves from exploratory to standardized.

One more point: control is only half the story. Validation is increasingly expected. That means growing interest in oxygen measurement (for example, dissolved oxygen in media using optical or fiber-optic probes) and in documentation that shows what cells actually experienced.

What buyers will prioritize

As hypoxia systems move from specialist tools to common infrastructure, purchasing criteria are shifting toward reliability and workflow fit. Expect researchers to care more about oxygen stability during repeated access, and about keeping workflows fully contained so cells can be handled under controlled oxygen, not just incubated there. Partial-pressure control (mmHg or kPa) is also getting more attention because it maps more cleanly to in vivo physiology and helps avoid confusion when barometric pressure changes. Beyond that, data integrity (logging and traceability), service support, practical contamination control, and ergonomics are increasingly part of the checklist.

This is where the workstation concept matters. An oxygen-controlled incubator helps during incubation. A workstation supports the experiment itself, including feeding, passaging, and sampling, without returning cells to atmospheric oxygen between steps.

Oxford Optronix’s HypoxyLab is one example of this workstation approach. It’s a hypoxia workstation with armports, so cells can be manipulated without being brought back into atmospheric oxygen. The system controls O₂, CO₂, temperature, and humidity, and supports partial-pressure-based oxygen regulation.

As Dr. Michael Rau (Oxford Optronix Sales Director) puts it:

“There has been a clear shift in the scientific community towards recognizing the importance of maintaining physiological oxygen levels during cell culture and in vitro cellular studies more broadly. Systems such as the HypoxyLab deliver absolute partial-pressure oxygen control, immune to barometric fluctuations or laboratory altitude, while supporting fully contained in vitro incubation workflows. As scientists strive to move their research away from in vivo models the availability of tools such as HypoxyLab has become ever more important.”

Whether a lab chooses that platform or another, these are the themes quickly becoming standard expectations.

The simple forecast

Animal use will not vanish overnight, nor should it, but the incentives are shifting. As NIH pushes funding toward more human-relevant approaches, and the FDA encourages NAM data in submissions, more labs will need robust, reliable in vitro workflows.

At the same time, the research community is increasingly aware that oxygen can’t stay a footnote. It’s a variable that can make a model more physiological and, in many cases, more translational.

Put those together and the conclusion is straightforward: demand for practical, reproducible oxygen control will rise. In 2026 and beyond, hypoxia workstations will likely be purchased less for “performing hypoxia experiments” and more for doing better biology.